LITHIUM POLYMER BATTERY

IEC62133-2-2017

What is IEC62133-2:2017 Certification for Lithium Polymer Batteries?

IEC62133-2:2017 is the most important standard for exporting lithium polymer batteries, including those used in IT Equipment, tools, laboratory, household, and medical equipment.

bihuade Battery Co., Ltd is the industry leader in manufacturing lithium polymer batteries. We can help our customer to apply IEC62133-2:2012 test report, IEC62133-2:2017 test report and IEC62133 certifications. More information, please contact us.

In December 2012, the International Electrotechnical Commission (IEC) officially released the IEC62133-2:2012 (2nd Edition), an international safety standard for lithium polymer batteries products. This standard is mainly for the safety requirements of single cell batteries and battery packs and portable sealed single cell batteries and battery packs containing alkaline or non-acid electrolytes (including lithium polymer batteries, lithium ion(Li-Ion) cells, nickel-hydrogen batteries, nickel-cadmium batteries, etc.).

In February 2017, IEC released a new version—— IEC 62133-2:2017, our company also can apply this test report for you.

Part I: Cells

The second edition of IEC62133 have the most impact on lithium polymer cells manufacturers and dealers, it also important for company who use the lithium polymer cells. The changes related to lithium polymer cells fall into three categories:

• Cancel redundant tests with other standards

• Modify existing tests

• Completely new requirements

1.Cancel redundant tests with other standards

The main focus is to delete the items covered by the United Nations Manual Of Tests and Criteria(UN38.3). The tests deleted are:

Vibration

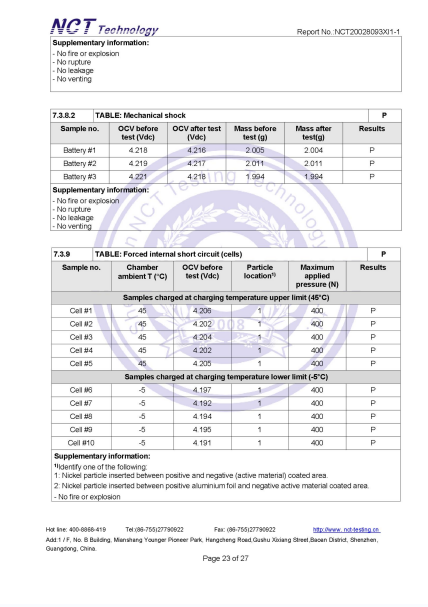

Mechanical Shock

Low Pressure(Altitude Simulation)

Cell Protection Against High Rate Charging(not a UN38.3 test)

3.Completely new requirements

The most significant change in the second edition is the addition of a new test——Forced Internal Short Circuit test. The test procedure very explicitly describes a method that requires the test facility to fully charge a Lithium polymer cell, then open it and remove the jellyroll. Once the cell is removed from the can, a small Nickel particle of a specific shape and size is to be place in a very specific location of the cell jellyroll. Following the placement of the particle, the affected jellyroll is to be crushed.

2.Modify existing tests

The most important of these changes is related to how the sample is prepared for testing. In the first edition of the standard, samples were charged at room temperature (20°C ±5°C) according to the manufacturer’s recommended charging method. The second edition includes two charging processes: one at room temperature, and one new program at high and low specified operating temperature ranges (10°C and 45°C if not stated). The new charging method also requires charging at the maximum rated charge current of the product. This process only requires samples at the cell level for short circuits, thermal abuse, crushing, and forced internal short tests.

In the constant voltage test, a continuous low-rate charge test was corrected to a constant charge. This modified test requires the battery to be charged for 7 days at the manufacturer’s recommended charge current and voltage limits.

Modifications to the crush test included clarification of the test, indicating that the crushing only needs to be done along the broadside of the cell. In addition, termination criteria for 10% deformation of cells were also added.

A more important change is to divide the short circuit into separate parts of the battery and the battery. The second version of the cell was modified to contain only one test temperature and provide a more stringent range of circuit resistances.

Part II: Batteries

For lithium polymer batteries manufacturers, the IEC62133-2:2012 proposal will have less impact on lithium polymer battery manufacturers than battery suppliers. Lithium polymer batteries manufacturers’ testing and demand will actually be reduced. The changes related to lithium polymer batteries fall into three categories:

• Revised Charging Procedure

• Reduced Sample Requirement

• New testing

1.Revised Charging Procedure

Similar to the cell level charging process changes, the lithium polymer batteries level will have a modified charging process, but this will only affect the battery level of a test.

This change comes from Japan’s lithium polymer batteries and battery test requirements, and it state that samples used for short-circuit testing must be charged in an environment which is equal to the ambient temperature upper and lower: assumes 45°C and 10°C if not provided by the manufacturer. All other tested units on the battery level were charged at room temperature (20°C).

2. Reduced Sample Requirement

The subcommittee’s test requirements for lithium polymer batteries are more comprehensive than ever. Therefore, the amount of test required by IEC 62133-2:2012 at the battery level has dropped significantly. The testing that has been completely removed as a result of this review is:

Vibration

Temperature Cycling

Mechanical Shock

The result is that the change reduces the required number of samples for testing from 31 for First Edition testing to 21 for Second Edition testing.

3.New Test

A new test has also been added to the battery level, designed to simulate the battery charging time longer than the manufacturer’s use of a higher charging rate.

This test is performed on a fully discharged five battery packs, and the charge the batteries with a current of two times the rated current, and an upper voltage limit that is set to the maximum voltage available from the charger to the battery. If you do not know the charger’s maximum voltage, 5 volt per cell (or cell string) will be used. The current is maintained until the maximum charge voltage is reached and the temperature is monitored during the test.

Part III: LP403035 420mAh IEC62133-2:2012 Test report

1. General product information

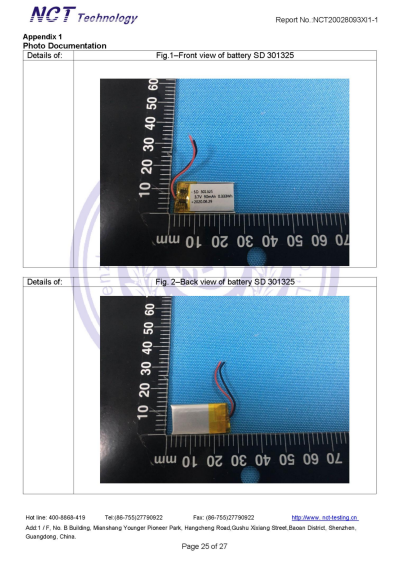

This lihtium polymer battery is constructed with one pouch cell, and has over-discharge, over current and short-circuits proof circuits. For example: LP403035 420mAh 3.7V

2. Tests Performed(name of test and test clause):

Test items:

Type test conditions

Charging procedures for test purpose

Continuous charging at constant voltage(cells)

Moulded case stress at high ambient temperature(battery)

External short circuit(cell)

External short circuit(battery)

Free fall

Thermal abuse(cells)

Crush(cells)

Over-charging of battery

Forced discharge(cells)

Transport tests

Test conclusion:

Lithium Polymer Battery submitted by Liter energy battery Battery Co.,Ltd are tested according to IEC62133-2: 2012(2nd Edition) Secondary cells and batteries containing alkaline or other non-acid electrolytes Safety requirements for portable sealed seconds cells. and for batteries made from them, for use in portable applications.

Test result: Pass.

3. LP403035 IEC62133 Test Report

IEC62133-2: 2012(2nd Edition) | ||

Clause | Requirement – Test | Verdict |

4 | Parameter measurement tolerances | P |

5 | General safety considerations | P |

Cells and batteries subject to intended use be safe and continue to function in all respects | P | |

Cells and batteries subject to reasonably foreseeable misuse do not present significant hazards | P | |

5.2 | Insulation and wiring | P |

Internal wiring and insulation are sufficient to withstand maximum anticipated current, voltage and temperature requirements | P | |

Orientation of wiring maintains adequate creep age and clearance distances between conductors. Mechanical integrity of internal connections is sufficient to accommodate conditions of reasonably foreseeable misuse. | P | |

5.3 | Venting | P |

Battery cases and cells incorporate a pressure relief mechanism or are constructed so that they relieve excessive internal pressure at a value and rate that will preclude rupture, explosion and self-ignition. | P | |

Encapsulation used to support cells within an outer casing does not cause the battery to overheat during normal operation no inhibit pressure relief. | P | |

5.4 | Temperature/voltage/current management | P |

The batteries are designed such that abnormal temperature rise conditions are prevented. | P | |

Means is provided to limit current to safe levels during charge and discharge. | P | |

The batteries are designed such that within temperature, voltage and current limits specified by the cell manufacturer. | P | |

Batteries are provided with specifications and charging instructions for equipment manufacturers so that associated chargers are designed to maintain charging within the temperature, voltage and current limits specified. | P | |

5.5 | Terminal contacts | P |

Terminals have a clear polarity marking on the external surface of the battery | P | |

The size and shape of the terminal contacts ensure that they can carry the maximum anticipated current. | P | |

External terminal contacts surfaces are formed from conductive materials with good mechanical strength and corrosion resistance. | P | |

Terminal contacts are arranged to minimize the risk of short circuits. | P | |

5.61 | Protective circuit components are added as appropriate and consideration given to the end-device application | P |

5.6.2 | Design recommendation for lithium system only | P |

For the battery consisting of a single cell or a single cellblock: -charging voltage of the cell does not exceed the upper limit of the charging voltage specified in Clause 8.1.2, Table 4: or | P | |

-Charging voltage of the cell does not exceed the different upper limit of the charging voltage determined through Clause 8.1.2, NOTE1. | P | |

5.7 | Quality plan | P |

The manufacture has prepared a quality plan defining the procedures for the inspection of materials , components, cells and batteries and which covers the process of producing each type of cell and battery. | P | |

6 | Type test conditions | P |

Tests were conducted with the number of cells or batteries as outlined in Table 2 of IEC62133 with cells or batteries that were not more than six months old. | P | |

Unless noted otherwise in the test methods, thieving was conducted in an ambient of 20°C±5°C. | P | |

8 | Specific requirements and tests | P |

8.1 | Charging procedure for test purposes | P |

If a cell’s specified upper and/or lower charging temperature exceeds values for the upper and/or lower limit test temperatures of Table 4, the cells were charged at the specified values plus 5°C for the upper limit and minus 5°C for the lower limit. | P | |

A valid rationale was provided to ensure the safety of the cell(see Figure A.1) | P | |

8.2 | Intended use | P |

8.2.1 | Continuous charging at constant voltage(cells) | P |

Fully charged cells are subjected for 7 days to a charge as specified by the manufacturer. | P | |

Results: No fire, no explosion, no leakage | P | |

8.2.2 | Moulded case stress at high ambient temperature(battery) | P |

Fully charged batteries according to the first procedure in 8.1.1, the batteries were placed in an air-circulating oven at a temperature of 75°C±2°C for 7 hours. Afterwards, they are removed and allowed to return to room temperature. | P | |

8.3 | Reasonably foreseeable misuse | P |

External short circuit(cell) | P | |

The case temperature declined by 20% of the maximum temperature rise | P | |

8.3.2 | External short circuit(battery) | P |

The batteries were tested until not of the following occurred: -24 hours elapsed | P | |

8.3.3 | Free fall | P |

Ambient temperature of 20°C±5°C. | P | |

Fully charged cells or batteries were dropped 3 times from a height of 1.0m onto a concrete floor. | P | |

After the test, the cell or battery shall be put on rest for a minimum of one hour and then a visual inspection shall be performed. | P | |

Results: No fire, no explosion | P | |

8.3.4 | Thermal abuse(cells) | P |

The cells were held at 130°C±2°C for: -10 minutes Results: No fire. No explosion | P | |

8.3.5 | Crush(cells) | P |

Each fully charged cell, charged according to the second procedure at the upper limit charging temperature in 8.1.2, is immediately transferred and crushed between two flat surfaces in an ambient temperature. | P | |

The crushing force was released upon: -The maximum force of 13 kN ±1 kN has been applied. Results: No fire. No explosion | P | |

8.3.6 | Over-charging of battery | P |

Test was continued until the temperature of the outer casing: -Reached steady state conditions(less than10°C charge in 30 minute period); or -Returned to ambient Results: No fire. No explosion | P | |

8.3.8 | Transport test | P |

Regulations concerning international transport of lithium polymer batteries are based on the UN Recommendations on the Transport of Dangerous Goods. Testing requirements are defined in the UN Manual of Tests & Criteria. Testing laboratory | P | |

9 | Information for safety | P |

The manufacturer of secondary cells ensures that information is provided about current, voltage and temperature limits of their products. | P | |

The manufacturer of batteries ensures that equipment manufacturers and, in the case of direct sales, end-users are provided with information to minimize and mitigate hazards. | P | |

10.2 | Battery marking | P |

Batteries marked in accordance with the requirements for the cells from which they are assembled. | P | |

Batteries marked with an appropriate caution statement. | P | |

11 | Packaging | P |

Cells or batteries were provided with packaging that was adequate to avoid mechanical damage during transport, handing and stacking. The materials and pack design was chosen to prevent the development of unintentional conduction, corrosion of the terminal and ingress of moisture. | P |