LITHIUM POLYMER BATTERY

UN38.3

What’s lipoly battery UN38.3? LiPoly Battery UN38.3 Test Items? LiPoly Battery Altitude Simulation | LiPoly Battery Temperature Test | LiPoly Battery Oscillation | LiPoly Battery Collision | LiPoly Battery External Short Circuit | LiPoly Battery Impression | LiPoly Battery Overcharge | LiPoly Battery Forced Discharge

What’s lithium polymer battery UN38.3?

Almost all Liter energy batteryy batteries need to pass Article 38.3 of the UNITED NATIONS to ensure the safety of Liter energy batteryy batteries during the transportation of dangerous goods. Manual and Criteria ST/SG/AC. 10/11/Rev.6, 38.3/Amendment 1

Our company bihuade Battery Co. can help customers to apply the UN38.3 test report. Each test takes one month after then you will get an official UN38.3 test report published by the third-party testing house (BCTC).

Lithium Polymer Battery UN38.3 Test Items

UN/DOT 38.2 Transportation Testing for Lithium Polymer Batteries 6th edition was issued in 2011. It includes eight sections.

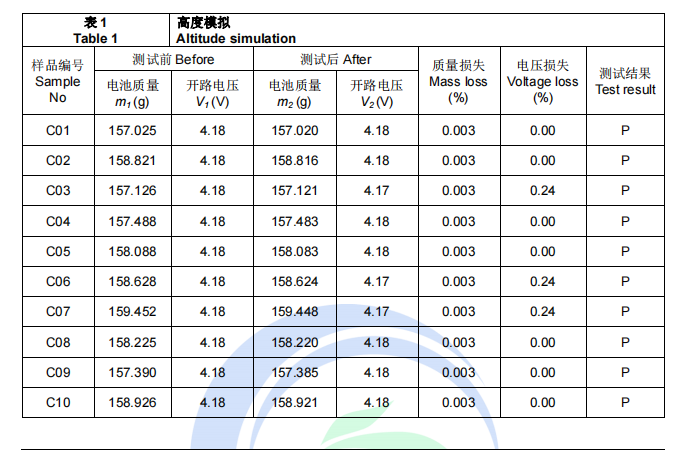

UN38.3.4.1: Lithium Polymer Battery Altitude Simulation

Test lithium polymer cells and lithium polymer batteries shall be stored at an 11.6 kPa or less for at least six hours at ambient temperature 20±5℃.

Lithium polymer and lithium polymer batteries meet this requirement if there is no mass loss, no leakage, no venting, no disassembly, no rupture, and no fire and if the open circuit voltage of each test cell or battery after testing is not less than 90% of its voltage immediately before this procedure. The requirement relating to energy is not applicable to test cells and batteries at fully discharged states.

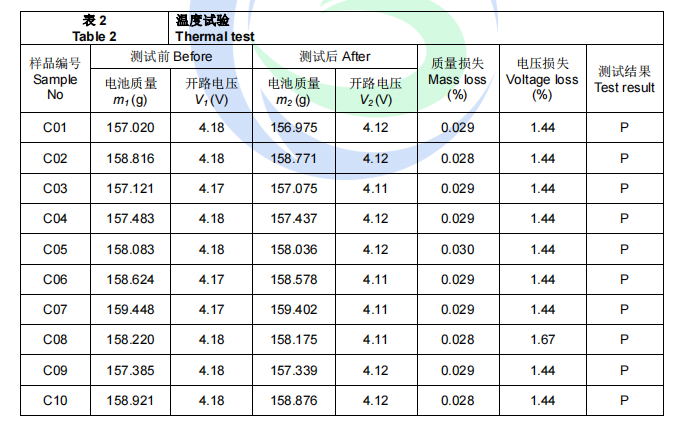

UN38.3.4.2: Lithium Polymer Battery Temperature Test

Test lithium polymer cells and lithium polymer batteries are to be stored for at least six hours at a test temperature equal to -72±5℃, followed by storage for at least six hours at a test temperature equal to -40±2℃. The maximum time interval between test temperature extremes is 30 minutes. This procedure is to be repeated ten times, after which all test cells and batteries are to be stored for 24 hours at ambient temperature.

Lithium polymer cells and lithium polymer batteries meet this requirement if there is no mass loss, no leakage, no venting, no disassembly, no rupture, and no fire and if the open circuit voltage of each test cell or battery after testing is not less than 90% of its voltage immediately prior to this procedure. The requirement relating to voltage is not applicable to test cells and batteries at fully discharged states.

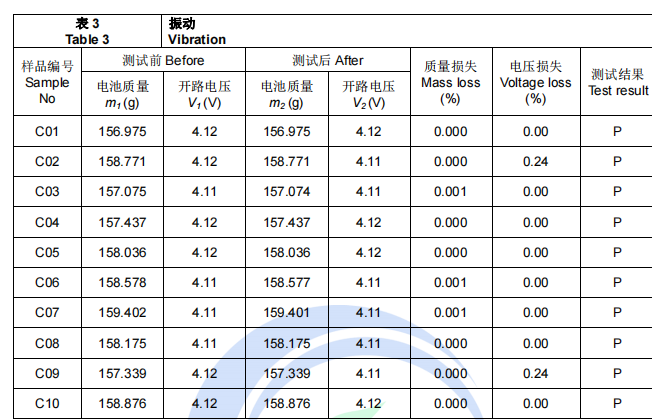

UN38.3.4.3: Lithium Polymer Battery Oscillation

Test lithium polymer cells and lithium polymer batteries are firmly secured to the platform of the vibration machine without distorting the cells in such a manner as to faithfully transmit the vibration. The vibration shall be a sinusoidal waveform with a logarithmic sweep between seven Hz and 200 Hz and back to seven Hz traversed in fifteen minutes. This cycle shall be repeated twelve times for a total of 3 hours for each of three mutually perpendicular mounting positions of the cell. One of the directions of vibration must be perpendicular to the terminal face.

The logarithmic wavelength sweep shall differ for cells and batteries with a gross mass of not more than 12 kg(cells and small batteries), and for batteries with a total mass of more than 12 kilograms (large Liter energy batteryy batteries).

For Liter energy batteryy cell and small lithium polymer batteries: from 7 Hz a peak acceleration of 1 gn is maintained until 18 Hz is reached. The amplitude is then maintained at 0.8mm (1.6mm total excursion) and the frequency increased until a peak acceleration of eight gn occurs( approximately 50Hz). Peak acceleration of eight gn is then maintained until the frequency is increased to 200Hz.

Lithium polymer cells and Lithium polymer batteries meet this demand if there is no mass loss, no leakage, no venting, no disassembly, no rupture, and no fire and if the open circuit voltage of each test cell or battery after testing is not less than 90% of its voltage immediately prior to this procedure. The requirement relating to voltage is not applicable to test cells and batteries at fully discharged states.

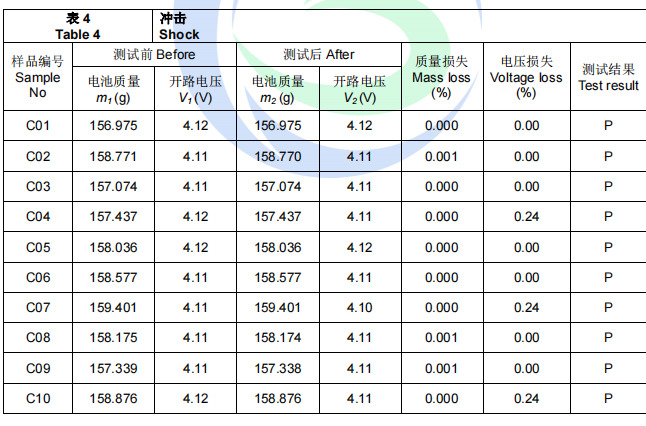

UN38.3.4.4: Lithium Polymer Battery Collision

Test lithium polymer cells and lithium polymer batteries shall be secured to the testing machine employing a rigid mount which will support all mounting surfaces of each test battery. Each lithium polymer cell shall be subjected to a half-sine shock of peak acceleration of one hundred and fifty gn and pulse duration of 6 milliseconds. Alternatively, large cells may be subjected to a half-sine shock of peak acceleration of fifty gn and pulse duration of 11 milliseconds. Each battery shall be subjected to a half-sine shock of peak acceleration depending on the mass of the Liter energy batteryy battery. The pulse duration shall be six milliseconds for small Liter energy batteryy batteries and 11 milliseconds for large lithium polymer batteries. The formulas below are provided to calculate the appropriate minimum peak accelerations.

Cells and batteries meet this requirement if there is no mass loss, no leakage, no venting, no disassembly, no rupture, and no fire and if the open circuit voltage of each test cell or battery after testing is not less than 90% of its voltage immediately prior to this procedure. The requirement relating to voltage is not applicable to test cells and batteries at fully discharged states.

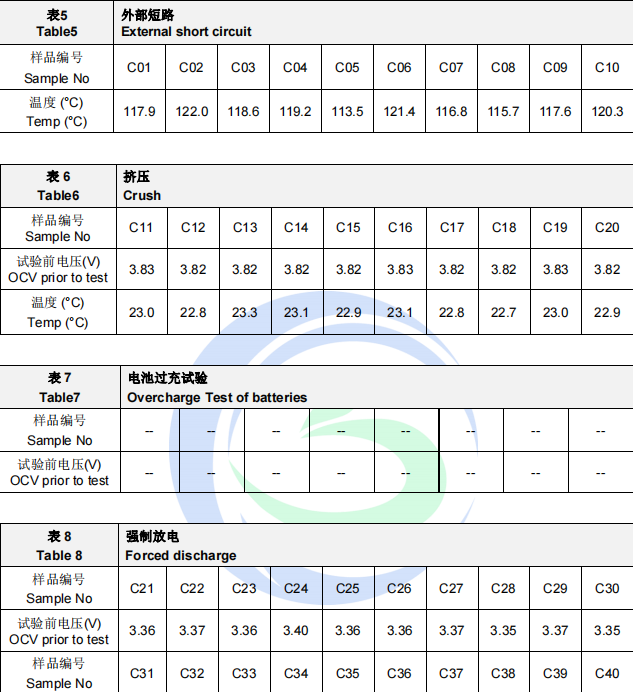

UN38.3.4.5: Lithium Polymer Battery External Short-Circuit

The lithium polymer cell or lithium polymer battery to be tested shall be temperature stabilized so that its external case temperature reached 57±4℃ and then the cell or battery shall be subjected to a short circuit condition with a total external resistance of fewer than 0.1 ohms at 57±4℃. This short circuit condition is continued for at least one hour after the cell or battery external case temperature has returned to 57±4℃.

Cells and batteries meet this requirement if their external temperature does not exceed 170℃ and there is no disassembly, no rupture, and no fire during the test and within six hours after the test.

UN38.3.4.6: Lithium Polymer Battery Impression

Test Procedure- Crush (applicable to prismatic, punch, coin/button cells and cylindrical cells not more than 18mm in diameter). A cell or component cell is to be crushed between two flat surfaces. The crushing is to be gradual with a speed of approximately 1.5cm/s at the first point of contact. The crushing is to be continued until the beginning of the three options below is reached. (a) he applied force reaches 13 kN±0.78 kN;

A prismatic or punch cell shall be crushed by applying the force to the widest side. A button/coin cell shall be crushed by applying the force on its flat surfaces. For cylindrical cells, the crushing force shall be applied perpendicular to the longitudinal axis. Each test cell or component cell is to be subjected to one curse only. The test sample shall be observed for a further 6 h. The test shall be conducted using test cells or component cells that have not previously been subjected to other tests.

Lithium Polymer cells and component cells meet this requirement if their external temperature does not exceed 170℃ and there is no disassembly, no rupture, and no fire during the test and within six hours after the test.

UN38.3.4.7: Lithium Polymer Battery Overcharge

The charge current shall be twice the manufacturer’s recommended maximum continuous charge current. Tests are to be conducted at ambient temperature. The duration of the test shall be 24 hours. The minimum voltage of the test shall be as follows: When the manufacturer’s recommended charge voltage is not more than 18v, the minimum voltage of the test shall be the lesser of two times the maximum charge voltage go the battery or 22v.

There is no disassembly and no fire during the test and within seven days after the test.

UN38.3.4.8: Lithium Polymer Battery Forced discharge

Each lithium polymer cell shall be forced discharge at ambient temperature by connecting it in series with a 12v D.C. power supply at an initial current equal to the maximum discharge current specified by the manufacturer. The specified discharge current is to be obtained by connecting a resistive load of the appropriate size and rating in series with the test cell. Each cell shall be forced discharged for a time interval (in hours) equal to its related capacity divided by the initial test current) in ampere).

There is no disassembly and no fire during the test and within seven days after the test.